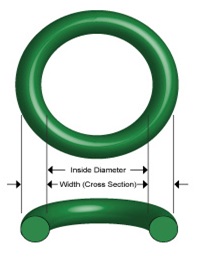

O Ring

Product Details:

O Ring Price And Quantity

- 500.00 - 5000.00 INR/Piece

- 50 Piece

- 2000 INR/Piece

O Ring Trade Information

- 50 Piece Per Week

- 2 Week

- Australia South America Eastern Europe Western Europe Middle East Central America Asia North America Africa

- All India

Product Description

| 'O' Rings |

|

|

||||